Table Of Contents

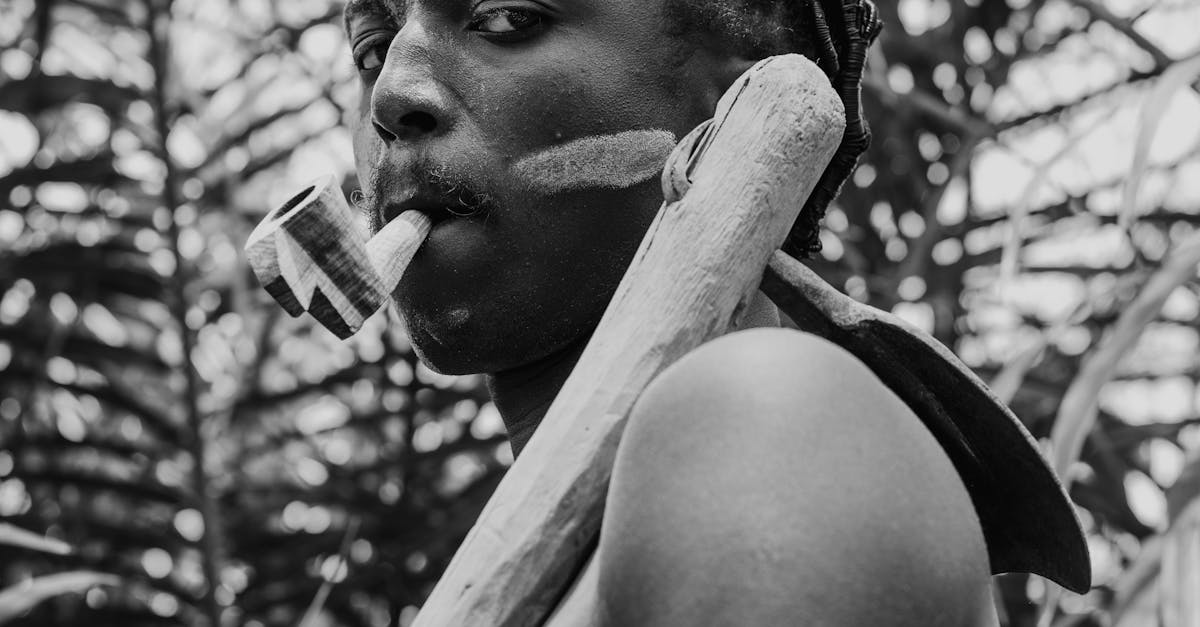

Installation Process of Pipe Coating

The installation process of pipe coating involves several key steps to ensure a thorough and effective application. Initially, the pipe’s interior surfaces are cleaned to remove any debris, rust or existing coatings. This can be achieved through techniques such as hydro jetting or mechanical scraping. Following the cleaning, a primer may be applied to enhance adhesion. The chosen coating material, often a resin or epoxy, is then carefully introduced into the pipe, ensuring an even distribution along the surfaces.

After the application, the coating needs to cure properly to form a durable barrier. This curing process can vary in duration based on the materials used and environmental conditions. Unlike pipe relining, which creates a new pipe within the old one, pipe coating focuses on bolstering the existing infrastructure. Overall, careful attention to detail during installation is crucial for the long-lasting performance of the coating system.

Steps Involved in Installation

The installation of pipe coating begins with a thorough inspection of the existing pipes. Crews often use advanced technology, such as cameras, to assess the condition of the infrastructure. This step is crucial for identifying any blockages or damage that may affect the coating process. Once the initial assessment is complete, the area surrounding the pipes is cleaned and prepared to ensure proper adhesion of the coating materials.

After preparation, the team applies the coating material using a spraying or rolling technique, depending on the specific project requirements. It is essential to ensure even application to maximise protection against corrosion and leaks. In some cases, additional curing agents may be used to enhance the durability of the coating. Alternative processes, such as pipe relining, may be explored if the damage is more significant, enabling a more robust and long-lasting solution for pipe repair.

Advantages of Pipe Lining

Pipe relining offers significant advantages, particularly in terms of cost-effectiveness. Traditional methods of pipe replacement often involve extensive excavation, which can lead to high costs in labour and restoration. In contrast, pipe relining requires minimal disruption to the surrounding area. The process replaces the inner lining of the pipe without the need for digging up the entire system, resulting in reduced expenses and a quicker installation timeline.

Another notable benefit of pipe relining is the long-term durability it provides. Once the new lining is installed, it creates a robust barrier against leaks and corrosion. This enhanced resistance prolongs the life of the pipes, reducing the likelihood of future repairs. Additionally, pipe relining is often less invasive, which can be particularly advantageous in urban settings where space and access are limited.

Benefits Over Traditional Methods

Pipe coating offers several benefits compared to traditional methods of pipeline maintenance. The process is less invasive, requiring minimal excavation which reduces disruption to the surrounding environment. This characteristic makes pipe coating a more efficient option for municipalities and property owners looking to repair or preserve their existing infrastructure without incurring significant costs or downtime.

In contrast to conventional repair methods, pipe relining can extend the lifespan of pipes significantly. This technique involves creating a new lining within the existing pipe, effectively sealing off cracks and leaks. The result is a restored functionality that helps prevent further damage and contamination, ensuring that the integrity of the plumbing system is maintained while also improving overall performance.

Advantages of Pipe Coating

Pipe coating offers several significant advantages over traditional methods of pipeline maintenance. One of its primary benefits is the enhancement of the pipeline’s internal condition, leading to improved flow and reduced friction. This is particularly crucial in older pipes where corrosion and build-up can severely hinder efficiency. Additionally, the materials used in pipe coating often provide a protective layer against future corrosion and wear, thereby extending the life of the pipeline.

Compared to pipe relining, pipe coating can be a less invasive solution. The coating process typically involves minimal disruption to the surrounding environment, making it more favourable in areas where excavation is impractical or undesirable. Moreover, the application techniques of pipe coating are versatile, adapting effectively to various pipe diameters and configurations, ensuring a comprehensive protective layer that addresses potential weak points in the pipeline system.

Benefits Over Traditional Methods

Pipe coating offers numerous advantages over traditional repair methods, particularly in terms of efficiency and longevity. Unlike conventional techniques that often require extensive excavation and disruption, pipe coating can be applied with minimal downtime. This results in significant cost savings for property owners, as the need for invasive digging is greatly reduced. The seamless application process also enhances the integrity of the pipes by creating a protective barrier against corrosion and other damaging elements.

On the other hand, pipe relining presents a modern alternative that can effectively restore damaged pipes without complete replacement. This method utilises a specially designed epoxy resin that forms a new pipe within the existing structure. The durability of the materials used in pipe relining often surpasses that of conventional piping systems, leading to longer-lasting results. Homeowners can enjoy peace of mind knowing that these advanced technologies address issues like leaks and blockages while preserving the overall infrastructure.

FAQS

What is pipe lining?

Pipe lining is a method of rehabilitation where a new pipe is inserted into an existing pipe to restore its structural integrity and prevent leaks.

What is pipe coating?

Pipe coating involves applying a protective layer to the exterior or interior surfaces of a pipe to prevent corrosion, wear, and other forms of damage.

How does the installation process differ between pipe lining and pipe coating?

Pipe lining typically requires access to the existing pipe for insertion, often using a resin-saturated liner that hardens in place. In contrast, pipe coating involves applying a liquid or spray-on material, which can require less intrusive access.

What are some advantages of pipe lining?

Pipe lining offers benefits such as minimal disruption to the surrounding area, a quick installation process, and the ability to restore pipe functionality without the need for excavation.

What are some advantages of pipe coating?

Pipe coating provides long-lasting protection against corrosion and environmental damage, can extend the life of existing pipes, and is often more cost-effective than full pipe replacement.